plug flow reactor example problem

A 2B 2D r A -25C A05 C B mol L -1 min -1. The reaction is irreversible and elementary.

Sizing A Plug Flow Reactor Pfr Youtube

The equation will he integrated for 80 percent conversion with Simpsons rule.

. Determine the plug-flow reactor volume necessary to produce 300 million pounds of ethylene a year from cracking a feed stream of pure ethane. The plug flow model has many practical applications. Y A 02 y B 05 y C 03 C is an inert.

Example 5 Application of Effectiveness For a second-order reaction in a plug flow reactor the Thiele modulus is SVQ and inlet concentration is C50 10. The volumetric flow rate of the feed is 50 Lmin. Made by faculty at the Universit.

The volumetric flow rate of the feed is 50 Lmin. Example Problem - Pyrolysis of Benzene. We want to achieve 80 conversion of ethane operating the reactorisothermally at 1100K at a pressure of 6 atm.

The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C. Diphenyl C 12 H 10 is an important industrial intermediate. Aspen Plus will be introduced with benzene pyrolysis reaction in a plug flow reactor in this tutorial.

Another sort of plug flow reactor could be described as open. An example for this procedure is the combustor example. I work through how we can determine the required volume of a plug flow reactor PFR given a demanded outlet concentration conversion using the PFR design.

A shower curtain the walls of a bathtub or a canyon wall seep all. One production scheme involves the pyrolytic dehydrogenetation of benzene C 6 H 6 1. One example is in the design of chemical reactors.

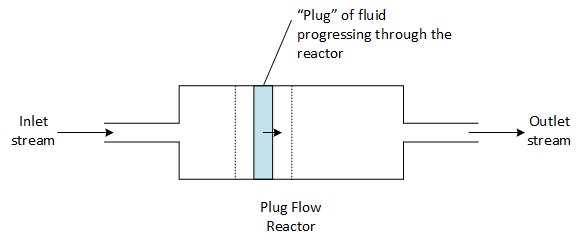

To solve this problem the reactor can be initialized with a high temperature andor radical concentration. In plug flow the velocity of the fluid is assumed to be constant across any cross-section of the pipe perpendicular to the axis of the pipe. Essentially no back mixing is assumed with.

Develop equations to determine plug flow reactor size for 50 conversion of reactant A. The next three pages will present the details and the data. The reaction is gas-phase in an isothermal PFR and is at 50 atm pressure and 55C.

Despite offering a high rate of substrate conversion plug-flow reactors are seldom suggested for biological treatment of water demanding cell growth because of inherent difficulties in providing continuous inoculum of cells as well as in maintaining desired pH and oxygen supply along the length of the reactor. Develop equations to determine plug flow reactor size for 50 conversion of reactant A. The plug flow model assumes there is no boundary layer adjacent to the inner wall of the pipe.

If the reactants are not reactive enough the simulation can result in the trivial solution that inflow and outflow states are identical. The plug flow reactors describe above may be described as closed in that they are enclosed in a pipe-like geometry. But a plug-flow reactor may be used successfully in bioprocesses.

A problem can be the ignition of a CSTR. A 2B 2D r A -25C A 05 C B mol L-1 min-1.

Plug Flow Reactor Overview Youtube

Isothermal Plug Flow Reactor Part 1 Youtube

Elements Of Chemical Reaction Engineering

Plug Flow Reactor Pfr Mass Balance And Reaction Speed

Plug Flow Reactor Pfr Sizing And Conversion Example Youtube

Summary Of Mixing And Flow Regimes In Flow Reactors A Radial Versus Download Scientific Diagram

Introduction To Energy Balances For Plug Flow Reactors Youtube

Experimental Setup Of The Plug Flow Reactor With Tof Ms Download Scientific Diagram

Plug Flow Reactor An Overview Sciencedirect Topics

Matlab In Chemical Engineering At Cmu

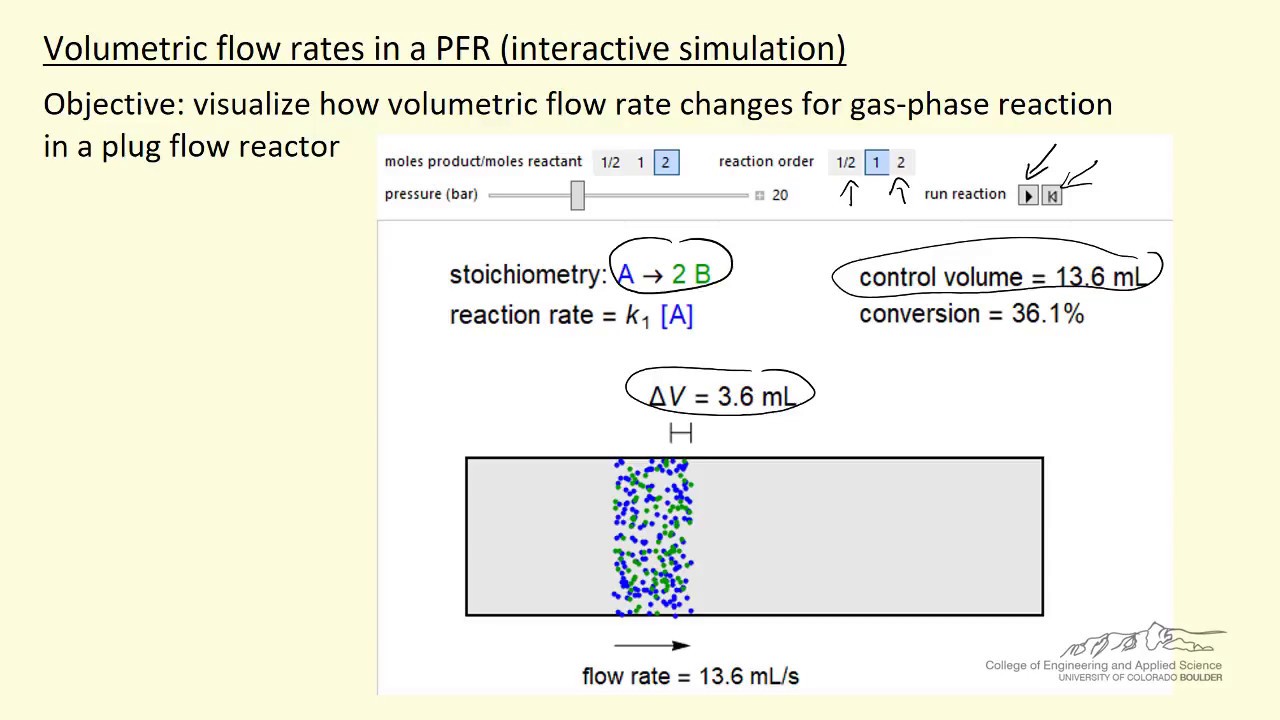

Volumetric Flow Rates In A Plug Flow Reactor Interactive Simulation Youtube

1 4 Continuous Flow Reactors Elements Of Chemical Reaction Engineering Mole Balances Informit

Mole Balance On A Plug Flow Reactor Youtube

Thoughts On Problem Solving Pfr Cstr Example

An Inclined Plug Flow Reactor Design For Supercritical Water Oxidation Sciencedirect

1 4 Continuous Flow Reactors Mole Balances In Chemical Reaction Engineering Informit